BLRT Rekato has a production hall with an area of 6,420 m2, equipped with a large number of specialized machine tools for manufacturing pipelines, profile structures and metal processing.

Our main areas of activity:

- Manufacture and installation of alloy and stainless steel, plastic, aluminum, copper pipelines.

- Modernization of marine fuel systems, fire extinguishing systems, ballast water treatment systems, scrubbers and other systems.

- Manufacture, repair and maintenance of hydraulic systems.

- Maintenance and repair of heat exchangers.

- Maintenance of pressure vessels.

- Manufacture, repair and maintenance of boilers.

- Repair and maintenance of valves.

- Production of auxiliary metal structures, foundations and railings.

Production hall is divided into the following sections:

| Section | Floor area, m2 | Crane lifting capacity, tons |

| Stainless steel structures processing and manufacturing section |

932 | 1 х 3,2 |

| Steel pipe processing and manufacturing section |

2 039 | 4 х 3,2 |

| Valve repair and maintenance section | 750 | 1 х 3,2 |

| Heat exchangers and boilers maintenance section |

1 819 | 1 х 3,2 |

| Lathe section | 310 | 1 х 3,2 |

| Hydraulic systems manufacturing and repair section |

570 | 1 х 3,2 |

Our list of services also includes:

- Sandblasting and ultrasonic cleaning.

- Automatic, semi-automatic and manual welding.

- Mechanical, plasma and oxyfuel gas cutting of pipes, profiles and sheet metal.

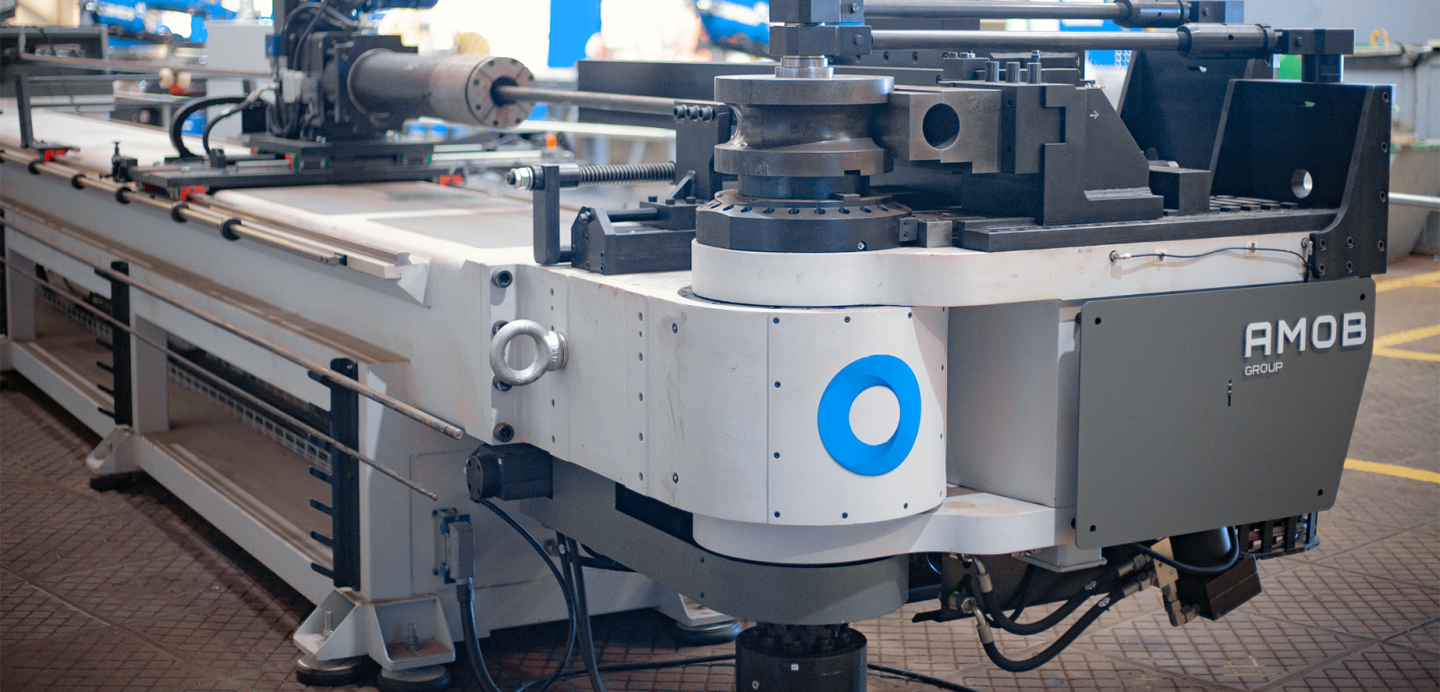

- Bending of 60 – 245 mm diameter pipes with 3 – 12 mm wall thickness.

- Bending of sheet metal with length 350 – 3 500 mm and thickness 3 – 12 mm.

- Hot-dip galvanizing and acid treatment of pipes up to 13.8 m in length.

- Quality control of welding by radioscopy, ultrasound and pressure test with pressure up to 300 bar.

Quality of products is tested in a certified laboratory at customer’s request.